Control System Validation

SIERRA PROVIDES REGULATORY COMPLIANT SYSTEMS & SERVICES TO SUPPORT LIFECYCLE PROJECT IMPLEMENTATION.

Life Science Clients – Controlled Project Delivery

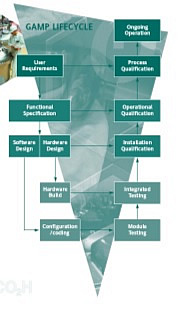

Sierra’s Quality Management System is based on ISO9001:2000. Many of our pharmaceutical and biotechnology customers request work to the GAMP Guide for validation of Automated Systems - guidelines which have become the de facto standard for Good Automated Manufacturing Practice in the healthcare industries.Sierra can offer validation activities throughout your project lifecycle. Sierra has a long history of projects successfully validated to GAMP guidelines including many which are now operating in FDA regulated environments

Sierra’s Quality Management System is based on ISO9001:2000. Many of our pharmaceutical and biotechnology customers request work to the GAMP Guide for validation of Automated Systems - guidelines which have become the de facto standard for Good Automated Manufacturing Practice in the healthcare industries.Sierra can offer validation activities throughout your project lifecycle. Sierra has a long history of projects successfully validated to GAMP guidelines including many which are now operating in FDA regulated environments

Planning

Hosting of Supplier Audit

Sierra is always happy to host supplier audits prior to placement of an order. A recent supplier audit concluded: “Sierra were able to demonstrate a good working knowledge of both the GAMP and FDA requirements. The project file reviewed as part of this audit highlighted their ability to adhere to the regulated guidelines”

Specification

Generation of Functional Specification

The functional requirements outlined in the customer’s user requirement specification are used to develop a functional specification to GAMP5. The document covers functions to be performed, data requirements, interfaces and non-functional attributes such as availability and maintainability. A traceability matrix cross-references each function back to the user requirements

Generation of Factory Acceptance Test Specification

A factory acceptance test specification is prepared to GAMP5 . This sets out testing procedures and the test set-up to be used as well as actual test scripts. A traceability matrix cross-references each test back to the functional specification and hence the user requirements.

Generation of Hardware Design Specification

A hardware design specification to GAMP5 includes a full drawing package plus details of computer systems, instruments, I/O systems to be supplied. Details of environment and required supplies are included.

Generation of Hardware Test Specification

The hardware test specification to GAMP4 covers hardware visual checks, power up and diagnostic checks.

Generation of Software Module Specifications

For each Category 5 software item, a module specification is prepared to GAMP5

Generation of Software Module Test Specifications

For each Category 5 software item, a module test specification is prepared to GAMP5

Generation of IQ Specification

The IQ specification to GAMP4 covers hardware visual checks, power up and diagnostic checks to be performed in order to confirm correct installation on site.

Generation of OQ Specification

The OQ specification to GAMP5 covers functional and interface tests to be performed in order to confirm correct operation of the system.

Production of Software

Software is produced to GAMP5 . Formal peer review of code is carried out for each Category 5 item.

Production of Hardware

Sierra’s ISO9001 procedures cover manufacture of Sierra Control System , purchase of bought-out hardware and integration of

both into standard or custom enclosures.

Implementation

Installation

Sierra can offer installation assistance as required.

Installation Qualification

IQ against the approved specification is carried out by a Sierra engineer, witnessed by the customer to confirm correct installation of the system.

Operational Qualification

OQ against the approved specification is carried out by Sierra engineers and customer together to confirm correct operation of the system.

Performance Qualification

Sierra can offer site assistance during the process qualification.

Validation Report

Although the validation report is the responsibility of the customer, results from each stage of testing are designed to be easily ‘pulled in’ as evidence of phase completion. Tabular appendices are provided for test progress and faults raised.

Verification

Hardware Acceptance Test

The customer is invited to witness hardware acceptance to the approved test specification.

Software Module Test

For each Category 5 software item, a module test is carried out to the approved test specification.

System Integration

Hardware and software are integrated into a complete system.

Integrated Test

Sierra engineers run through all the tests in the factory acceptance test specification prior to inviting the customer witness the tests.

Reporting and Handover

Factory Acceptance Test

The customer is invited to witness functional testing to the approved test specification.

Ongoing Operation

Service Level Agreements

Service level agreements to GAMP5 are available for a range of different cover levels.